(PDF) Planetary Ball Mill Process in Aspect of

PDF On Apr 28, 2014, Huynh Xuan Kho and others published Planetary Ball Mill Process in Aspect of Milling Energy Find, read and cite all the sample preparation mill PULVERISETTE 5/4 classic line planetary ball horizontal for powders Rotational speed: 50 rpm 400 rpm Ideal for large quantities The Planetary Planetary ball mill All industrial manufacturersPlanetary ball mills are used for pulverizing solid sample materials by impact and friction The extremely high centrifugal forces result in very high pulverization energy and Planetary Ball Mills RETSCH fine grinding of materials

Planetary Mills – fritsch

Planetary Ball Mills HighPerformance allrounders in routine laboratory work Highspeed and versatile Planetary Mills are ideally suited for fine grinding of hard, mediumhard, Processes inside planetary ball mills are complex and strongly depend on the processed material and synthesis and, thus, the optimum milling conditions have to be assessed for each individual system The present Process engineering with planetary ball mills RSC 2019年2月1日 Planetary ball mills provide high energy density due to the superimposed effect of two centrifugal fields produced by the rotation of the supporting disc and the Effects of the speed ratio on the efficiency of planetary mills

Ball milling: a green technology for the

Abstract Ball milling is a simple, fast, costeffective green technology with enormous potential One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical Here a short view of the FRITSCH instrument ranges: Mills for crushing, micromilling, mixing, homogenising of hardbrittle, fibrous, analysis sieves ball mills bead mills +59 2 Planetary Ball Mills Companies From Around The WorldPlanetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has extended to mechanochemical Process engineering with planetary ball mills RSC

Finite Element and Multibody Dynamics Analysis

2022年12月29日 Finite Element Analysis To ensure the structural integrity of the ball mill, a quasistatic stress analysis simulation was conducted on SolidWorks The entire parts were meshed using 4node solid tetrahedral 2017年11月1日 Burmeister et al modelled the stressing conditions of dry grinding in planetary ball mills based on DEM and validated the model by comparing the measured and calculated input power values [13 Dry grinding in planetary ball mills: Evaluation of a stressing 2023年5月15日 Ballmills are categorized into four types depending on the motion generated to produce momentum in grinding balls and act upon the material with various milling forces These are planetary, tumbling, vibratory, and attrition mills 31 Planetary ball mill Planetary ball mills are simple and efficient in producing ground/pulverized materialBallmilling: A sustainable and green approach for starch

Open Access proceedings Journal of Physics: Conference

2021年11月15日 planetary ball mill gearing result in very high pulverization energy and therefore short grinding times [10,11] The type of planetary ball mill used in industry is the Retsch Planetary Ball mill PM100 [12] Furthermore, the principles of horizontal ball mill operations are limited regarding the fineness of the powder after milling2019年2月15日 A cascading motion pattern was always observed in the absence of mill feed and with a typical ball filling ratio of 03 Nevertheless, by increasing the ball filling ratio or the friction conditions, due to the presence of the mill feed, the dynamics of balls changed to a cataracting regimeEffects of the speed ratio on the efficiency of planetary millsThe ideal Ball Mill for standard applications Max speed 650 rpm Up to 10 mm feed size and 01 µm final fineness 1 grinding station for jars from 12 ml up to 500 ml Jars of 12 – 80 ml can be stacked (two jars each) GrindControl Planetary Ball Mill PM 100 RETSCH highest fineness

Ball milling as an important pretreatment technique in

2021年8月12日 The load acted by grinding balls on lignocellulosic biomass is considerably higher, compared to the conventional ball mill and planetary ball mill Important factors affecting the impact forces acting on the powders are the rate of milling, vibrational frequency, the amplitude of vibration, and the mass of the grinding balls [ 33 , 47 , 48 ]Planetary Ball Mill PM 400 The PM 400 is a robust floor model with 4 grinding stations and accepts grinding jars with a nominal volume from 12 ml to 500 ml It processes up to 8 samples simultaneously which results in a high sample throughput The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization Planetary Ball Mill PM 400 RETSCH powerful and quick 2020年10月13日 All milling experiments were conducted with the PM100 planetary ball mill (Retsch, Germany) with pauses in the milling cycles (30 min on, 30 min off) to prevent overheating of the unit and to Mechanochemical conversion kinetics of red to black

Ball milling: a green technology for the

The effect of ball mill on the morphological and structural features of cellulose has been described by Okajima and coworkers 20 They treated microcrystalline cellulose derived from cotton linters in a planetary ball 2020年2月12日 Inappropriate application of plant nutrients induces 40–70% loss of nutrients and causes contamination of land and water systems Nanofertilizers provide nutrients precisely to the plant’s requirement, and thus reduces the environmental loss of nutrients Synthesis of nanoparticles is carried out by either topdown or bottomup Synthesis of Nanofertilizers by Planetary Ball MillingPM 300 The Planetary Ball Mill PM 300 is a powerful and ergonomic benchtop model with two grinding stations for grinding jar volumes up to 500 ml This setup allows for processing up to 2 x 220 ml sample material per Retsch : Milling : Ball Mills : PM 300

Retsch : 粉碎设备 : 球磨仪 : PM 200

Download The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short grinding times The PM 200 can be found in virtually all industries 2022年1月3日 A planetary ball mill (Pulverisette seven premium line, Fritsch) equipped with stainless steel milling jars (80 ml filling capacity) and stainless steel balls were used During the milling process, the jar temperature was controlled between 35 and 45°C by using an external cooling system attached to the mill (VWR RC10 digital chiller) Kinetic Energy Dose as a Unified Metric for Comparing Ball Mills 2021年11月18日 Fig 1 Upper part: Examples of (a) a planetary ball mill (Fritsch planetary ball mill P7) and (b) a vibrational ball mill (Retsch mixer mill MM400) Lower part: Procedure of milling jar filling for (left) a planetary ball mill and (right) a vibrational ball mill (I) The empty milling jars are equipped with a seal and milling ballsThe mechanochemical synthesis of polymers RSC Publishing

Effects of rotational direction and rotationtorevolution

2002年7月1日 The rotational direction of a pot in a planetary ball mill and its speed ratio against revolution of a disk were studied in terms of their effects on the specific impact energy of balls calculated 2016年8月1日 Among highenergy ball mills, the planetary is a mechanically simple and versatile device for efficient grinding It is usually made of two or more jars, rotating at an angular velocity ω around their axis (see Fig 1), installed on a disk rotating at angular velocity ΩGrinding occurs by impact among the milling media (balls and jars), driven by Modeling of the planetary ballmilling process: The case Processing of SolidState Electrolytes in Planetary Ball Mills Planetary ball mills are most often used for laboratory synthesis of solid electrolytes, which may be attributed to the simplicity of the experimental setup, the high suitability for lab operation as well as the widespread use of this technological device [80, 91] Figure 2 Energy Storage Materials for Solid‐State Batteries: Design by

Analysis and Modelling of Bead Contacts in WetOperating

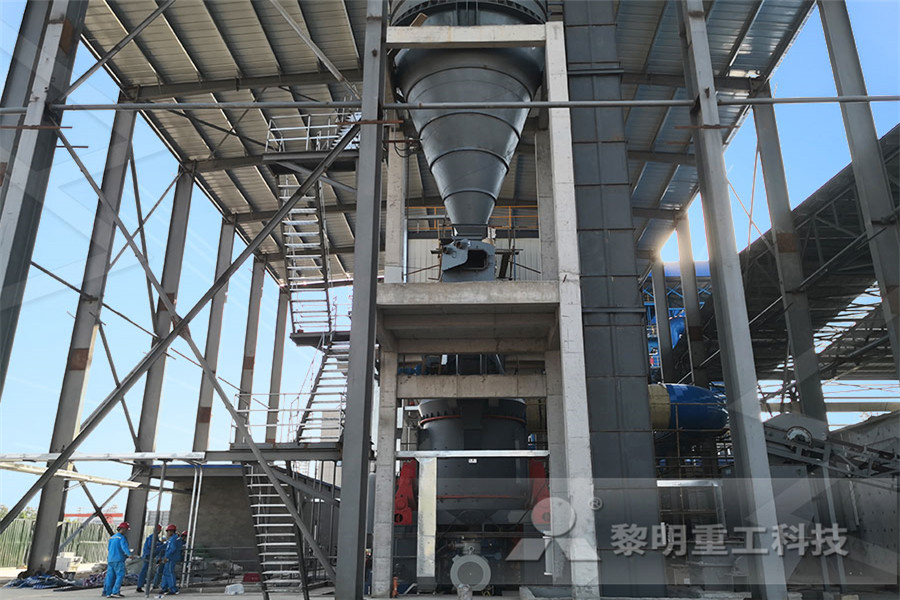

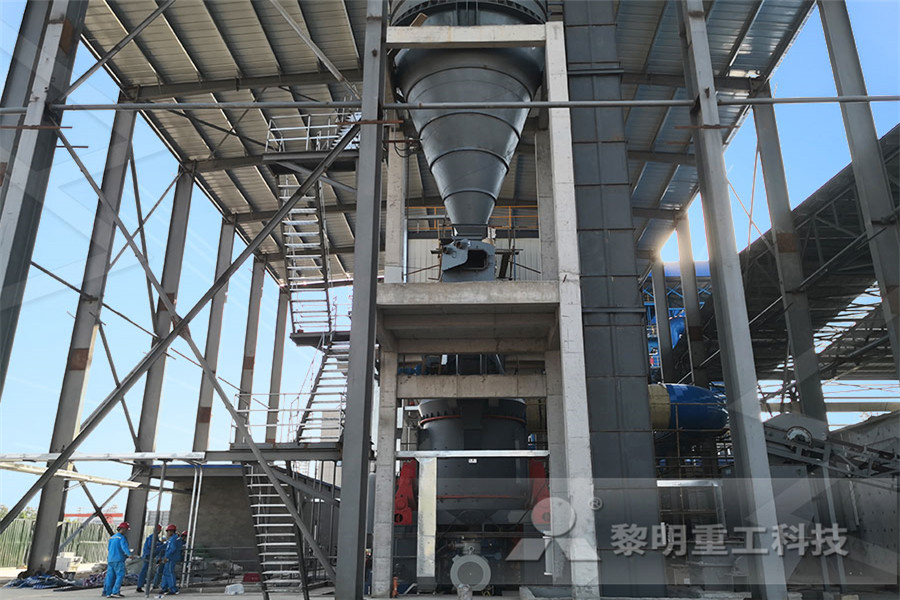

2015年6月1日 Three different mills, a cylindrical rotor, a disc stirrer, and a planetary ball mill were investigated by Beinert et al [17] using coupled CFD and DEM simulations, and analyses of bead movement 2023年8月15日 球磨机是物料被破碎之后,再进行粉碎的关键设备。这种类型磨矿机是在其筒体内装入一定数量的钢球作为研磨介质。它广泛应用于水泥,硅酸盐制品,新型建筑材料、耐火材料、化肥、黑与有色金属选矿 球磨机百度百科Highspeed and versatile Planetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls The grinding can be performed dry, in suspension or in Planetary Mills – fritsch

(PDF) Modelling of the HighEnergy Ball Milling

2021年1月1日 Abstract and Figures In this paper, the milling parameters of high energy ball mill (Fritsch Pulverisette 7) like vial geometry, number and size of balls and speed of the mill were modelled and 2004年8月1日 There have been constant endeavors to develop efficient mills of large size with continuous improvement in mill design Highenergy continuous planetary mills of capacity as high as 5000 kg/h are Planetary mills of periodic and continuous action Request PDF2022年9月16日 vibratory milling apparatus is much greater than that of planetary ball mill system; therefore, less time may be needed for the particle size reduction in the vibratory ball mills Here, the similar parameters need to be considered at time of milling process, ie, milling speed, milling time, grinding medium, atmosphere, etcRecent Developments on the Synthesis of

Room temperature ferromagnetic behavior in Cr IOPscience

2023年3月1日 Obtained powders were milled by a planetary ball mill system with a rotation speed of 400 rpm, in air and Ar, where the milling time was 15, 30, 60 min The crystal structure was characterized by powder Xray diffraction (XRD) measurement using CuKɑ line (λ = 154056 Å) at room temperature Sample morphology was measured by field 2020年3月5日 The type of planetary ball mill used in industry is the Retsch Planetary Ball mill PM100 [12] Furthermore, the principles of horizontal ball mill operations are l imited regarding the fineness of the(PDF) Analysis Of Alumina Particles Size And Shape 2023年1月11日 The process of ball milling and the materials that compose planetary ball mills are highly complex, and the existing research on the change in ballmilling energy is not mature The theoretical model of a ball mill was established for the first time to simulate the motion, collision process, energy transfer, and temperature change of small balls during Model Study of Mechanicochemical Degradation in a Planetary Ball Mill

Effect of stressing conditions on mechanochemical

2020年9月15日 Conclusions The Knoevenagel condensation of barbituric acid and vanillin was investigated as a solvent free mechanochemical model reaction in planetary ball mills The total power input, which includes the dissipation by headon collisions and shear stressing events, mainly determines the outcome of the mechanochemical Knoevenagel 2004年12月1日 Planetary ball milling was applied to white sorghum flour with the aim of modifying its thermal, structural and morphological properties Median particle size decreased from 572 μm a 208 μm ScaleUp Method of Planetary Ball Mill ResearchGate2016年5月30日 A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball size and number, jar geometry and velocity (PDF) DESIGN AND FABRICATION OF MINI BALL

/ planetary ball mill calculation pdf feeding system

Contribute to dihog/ development by creating an account on GitHub2021年8月18日 the planetary ball mill depend very much on the appropriate tuning of a multitude of milling variables Among the others, the number and size of the balls, the jar geometry and the velocity of revolving parts should certainly be mentioned The setup parameters strongly influence the ball trajectories,Effect of jar shape on highenergy planetary ball milling 2022年7月21日 The authors identified a model system using nickel catalysis to enable the coupling of 3bromoanisole and ethyl 4bromobutryrate using a planetary ball mill system, flushing the jars with a Mechanochemical techniques for the activation and use of

宋静中国科学院大学UCAS SEP 教育业务接入平台

2019年5月20日 (2)Mechanochemical destruction of DDTs with FeZn bimetal in a highenergy planetary ball mill (3)Evaluation of Cd availability by using DGT and traditional chemical extractions in agricultural soils from Hezhang county, Guizhou, China 第十四届植物技术国际会议 2021年3月1日 The balltoparticle filling mass ratio (BPR), defined as the amount of particles and balls placed in the mill pot, plays an important role in controlling the dissipated energy of the particles Planetary ball mills are one of the most frequently used highenergy mills owing to their structural simplicity and good operabilityDependence of the dissipated energy of particles on the 2019年8月1日 This method allows production of homogeneous materials starting from blended elemental powder mixtures produce a nickelbased superalloy Mechanical alloying (MA) is a solidstate powder processing technique that involves repeated cold welding, fracturing, and rewelding of powder particles in a highenergy ball millA review on mechanical activation and mechanical

Mixing methods for solid state electrodes: Techniques,

2023年5月15日 For both attritors and tumbler ball mills, the efficiency of the grinding is the best at 2/3 of the radius from the center, making them suitable for large scale milling [45] On the contrary, planetary ball mills (Fig 4 d) are compact in size and widely used at lab scale due to their easy handling and high versatility since several jars can be 2023年10月26日 FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill, PULVERISETTE 7 premium line, with 2 grinding stations is designed for a broad range of applications and ideally suited for lossfree grinding down to a final fineness of 100 nm (or less) of hard, mediumhard and brittle materialsPlanetary Mills Fritsch Milling and SizingPlanetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has extended to mechanochemical Process engineering with planetary ball mills RSC

Finite Element and Multibody Dynamics Analysis

2022年12月29日 Finite Element Analysis To ensure the structural integrity of the ball mill, a quasistatic stress analysis simulation was conducted on SolidWorks The entire parts were meshed using 4node solid tetrahedral 2017年11月1日 In the system, the highspeed camera Mako G40250 fps is fixed on the sun wheel rotating with the pot (Fig 1) Through this scheme valuable information in dry grinding conditions was obtained Dry grinding in planetary ball mills: Evaluation of a stressing 2023年5月15日 Ballmills are categorized into four types depending on the motion generated to produce momentum in grinding balls and act upon the material with various milling forces These are planetary, tumbling, vibratory, and attrition mills 31 Planetary ball mill Planetary ball mills are simple and efficient in producing ground/pulverized materialBallmilling: A sustainable and green approach for starch

Open Access proceedings Journal of Physics: Conference

2021年11月15日 planetary ball mill gearing result in very high pulverization energy and therefore short grinding times [10,11] The type of planetary ball mill used in industry is the Retsch Planetary Ball mill PM100 [12] Furthermore, the principles of horizontal ball mill operations are limited regarding the fineness of the powder after milling2019年2月15日 A cascading motion pattern was always observed in the absence of mill feed and with a typical ball filling ratio of 03 Nevertheless, by increasing the ball filling ratio or the friction conditions, due to the presence of the mill feed, the dynamics of balls changed to a cataracting regimeEffects of the speed ratio on the efficiency of planetary millsThe ideal Ball Mill for standard applications Max speed 650 rpm Up to 10 mm feed size and 01 µm final fineness 1 grinding station for jars from 12 ml up to 500 ml Jars of 12 – 80 ml can be stacked (two jars each) GrindControl Planetary Ball Mill PM 100 RETSCH highest fineness

Ball milling as an important pretreatment technique in

2021年8月12日 The load acted by grinding balls on lignocellulosic biomass is considerably higher, compared to the conventional ball mill and planetary ball mill Important factors affecting the impact forces acting on the powders are the rate of milling, vibrational frequency, the amplitude of vibration, and the mass of the grinding balls [ 33 , 47 , 48 ]Planetary Ball Mill PM 400 The PM 400 is a robust floor model with 4 grinding stations and accepts grinding jars with a nominal volume from 12 ml to 500 ml It processes up to 8 samples simultaneously which results in a high sample throughput The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization Planetary Ball Mill PM 400 RETSCH powerful and quick 2020年10月13日 All milling experiments were conducted with the PM100 planetary ball mill (Retsch, Germany) with pauses in the milling cycles (30 min on, 30 min off) to prevent overheating of the unit and to Mechanochemical conversion kinetics of red to black

هل اضع مسحوق كلور عادي في الغساله الفوق اتوماتك

آلة طحن الكرة السعر الهند

طیف تجهیزات فروش سنگ شکن در

حجر كسارة متحرك في جنوب افريقيا

محاجر الحجر الرملي للبيع

مطحنة الذهب النقالة للإيجار المملكة العربية السعودية

موزعين معدات التعدين

كسارة صخرية في الهند

كيفية صناعة البيوت المتنقلة

تستخدم المحمولة الفك أسعار محطم

الذهب مطرقة خام مطحنة

سنگ برای سنگ آهنسنگ آهن خرد کن برای سنگ زنی

ماكينه تشكيل وثني المواسير

المطاحن الطرد المركزي ختم الكرة المطاحن

حجر مطحنة المضغ

Opacity Limits For Portable Rock crusher

شعارات دوائر الحكومية العراق

برتقالي لآلة الطحن

مستوردي الماكينات في قطاع البناء بالجزائر

الكرة مطحنة الرسم

داني مطحنة الحديد

تبحث التعدين الحجر الجيري

مقاطع فيديو لآلات الطحن

مطحنة الكرة سهلة التركيب

أسعار المعدات السعودية لتعدين الماس

اسعار مطاحن البن

كسارة الحجر 500 طن لكل ساعة متنقلة

مطاحن الأسمنت المطاحن الأسطوانية العمودية استهلاك الطاقة

أن عملية الإنتاج الخام لوحة

الصانع آلات سحق الرمال في ألمانيا