An energy based comparison of vertical roller mills and

2015年3月10日 Comparison of vertical roller mills with tumbling mills on the lab and pilot scale Lab scale tumbling mills arranged in the (energy) optimized comminution sequence Energy control by torque measurement, dispersity control by permeametry2015年3月10日 The paper aimed to provide traceable measurement results to compare the energy consumption for grinding only of ball mills and vertical roller mills using lab scale An energy based comparison of vertical roller mills and tumbling mills 2021年1月1日 A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now Review on vertical roller mill in cement industry its

Modeling of energy consumption factors for an industrial

2022年5月9日 By initiating a CL for an industrial cement vertical roller mill (VRM), this study conducted a novel strategy to explore relationships between VRM monitored operational 2016年10月5日 Roller mills are operated with throughput capacities of more than 300 t/h of cement raw mix (Loesche mill, Polysius® double EnergyEfficient Technologies in Cement Grinding 2022年1月23日 The parameters of VRM are as follows: roller radius 340 mm, roller width 105 mm, roller inclination 13°, millstone radius 300 mm, millstone revolution rate 0–72 rpm, motor revolution rate 0–1000 rpm, Analysis and Optimization of Grinding

COMPARISON OF ENERGY EFFICIENCY BETWEEN A ROLLER MILL AND A HAMMER MILL

For roller mill grinding, roll gap was the most significant factor affecting energy requirement, followed by the roll speed differential For hammer mill grinding, screen opening size had 2010年2月28日 Roller mills simply “roll” or “crush” product between two revolving cylinders This latter process has the distinct advantage of requiring considerably less power, Hammermills versus roller mills WorldGrain2021年3月1日 The roller mills, in particular the rollerbowl mills, have found their extended application in the agrifood industry They are used for the milling and crushing of cereal grain, fertilizers and mineral raw materials, Selected Aspects of Modelling and Design

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 Abstract Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, bean mill G8 for animal feed rice corn Production capacity: 25,000 kg/h 40,000 kg/h The Rivakka Greenmaker G8 is a tractordriven roller mill for fresh or dry grain The mill 's serratededged, hardened rollers effciently pull grain inside and carefully Roller mill, Roller grinding mill All the agricultural 2015年3月10日 The energy savings of the vertical roller mill decrease for marble and hematite with increasing surface from about 62% at 2000 Blaine and 3400 Blaine respectively to 35% at 6000 Blaine For the siderite ore the energy savings show different behavior increasing from 48% at 3000 Blaine to 60% at 6000 BlaineAn energy based comparison of vertical roller mills and tumbling mills

A cement Vertical Roller Mill modeling based on the

2022年10月1日 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industries For the sectors above, the VRM is a powerful and energyintensive grinding field [1], [2] It is used to grind slag, nonmetallic ore, and other block 2015年3月10日 The Institute of Mineral Processing at the Montanuniversitaet Leoben in cooperation with the company CEMTEC has developed a pilot scale, 200 mm table diameter, vertical roller mill for energy controlled laboratory tests The mill provides the technical options to vary process parameters like airflow, mass flow, grinding force and An energy based comparison of vertical roller mills and tumbling mills 2021年10月13日 The vertical roller mill (VRM) which has gained wide acceptance in the cement industry and is used for grinding raw materials (mainly limestone), is a promising alternative A Technical and Economic Comparison of Ball Mill Limestone Comminution with a Vertical Roller Mill @article{Swart2021ATA, title={A Technical and Economic A Technical and Economic Comparison of Ball Mill Limestone

Hammer Mill or Roller Mill: Advantages Disadvantages

2022年12月29日 That dictates when to utilize hammer mills So my guidelines are as follows: Use roller mills: • For mash feed down to 500 microns • For large volumes of feed • To effectively control particles of all sizes • To reduce energy costs • In front of hammer mills when doing large volumes Use hammer mills:2010年2月28日 Roller mills, particularly single pass installations, require more care and attention than hammermills in order to achieve a consistent and accurate grind Ensuring the feed is spread thinly across the face of the roller mills can present some problems as mechanical feed gates can easily become obstructed, impairing the smooth and regular Hammermills versus roller mills WorldGrain2019年1月1日 In addition to using the integrated mill of each roller compactor, a standalone Frewitt mill was used with the same settings for all roller compactors to study the impact of the mill separated from the roller compaction process This comparison was used to test whether compaction of the formulation in different roller compactors to the same A systematic study of the impact of changes of roller

(PDF) Power Consumption Comparison between conventional and Two Roller

2023年3月4日 A traditional Sugar Mill, which currently runs at 6000 TCD, has been identified as a primary model for this upgrade By up gradation to 2roller mills, instead of 4roller or 6roller mills, this 2021年1月1日 Comparison among grinding technologies Ball mill V/s VRM For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over Review on vertical roller mill in cement industry its 2019年10月1日 A computational method for pass design of the fourroll rolling process for sizing of round sections The fourroll rolling process (4RP) enables the further evolution of sizing processes in Roll Pass Design Methods for Three and Four

COMPARISON OF GRINDING EFFICIENCY BETWEEN

1 天前 COMPARISON OF GRINDING EFFICIENCY BETWEEN BALL MILLS AND VERTICAL ROLLER MILLS IN COARSE GRINDING Yakup Umucu 1, Vedat Deniz 2,Osman Mart 1 Abdi Kemal Y!ce 1, Mehmet Fahri Sara" 32022年9月12日 80 mm e raw materials were mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) e raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter Modeling of energy consumption factors for an Raymond® roller mill upgrades flyer Pulverizing Aftermarket Line Card Raymond® Roller Mill 我们一直支持您 我们的伙伴关系意味着无论何时何地,只要您需要,我们都会随时支持您。凭借我们的全球网络和专业合作伙伴,我们确保永远在您身边 Raymond®辊磨——风扫式立式环辊磨机

Indicate Contributions from Several Radial

It was a Vertical Roller Mill is designed for rated capacity 215 TPH but its output was very low so specific power consumption was higher and contributing to loss in terms of production and in turn profitability 21 Tools Techniques Used 211 Data Collection2020年11月16日 Along with roller mills, disc mills are the main types of grinders used for milling grains of wheat, maize, and other crops during pulp preparation in pulp and paper industry) [33,34,35] Disc mills compare favorably to their analogs as they have a narrow particle size distribution, which depends on the gap between the discs Mechanochemical and Size Reduction Machines for Biorefining2020年3月1日 Roller mills have better energy efficiency compared to hammer mill and multicracker devices (Wondra et al, 1993; Vukmirović et al, 2016; Thomas et al, 2018) Grain type can also be a factor affecting energy consumption Comparison of Hammermill and Roller Mill Grinding and the Effect of Grain Particle Size on Mixing and Pelleting Size reduction in feed technology and methods for

OK™ cement mill The most energy efficient mill for

2019年4月10日 Proven commercially, the OK™ mill is the premier roller mill for finish grinding of Portland cement, slag and blended cements The mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is2023年11月2日 Lehi Roller Mills vs King Arthur Baking: SidebySide Brand Comparison Compare King Arthur Baking vs Lehi Roller Mills sidebyside Choose the best baking ingredients mix brands for your needs based on 1,407 criteria such as newsletter coupons, Apple Pay Later financing, Shop Pay Installments, autoship discounts and price King Arthur Baking vs Lehi Roller Mills: SidebySide Comparison 2020年11月1日 For the roller mill, several other strategies have been identified: wheat debranning before milling, combined with the stabilization of bran, middlings, and germ (Cappelli et al, 2020g); the development and improvement of automatic and adaptive mill plants (Campbell et al, 2012); and the use of break, sizing, and reduction systems to Improving roller milling technology using the break, sizing,

Cement grinding Vertical roller mills versus ball mills

2016年1月23日 The following presents a comparison of the two mill systems with reference to these issues Grinding process The grinding process in ball mills and vertical roller mills differ fundamentally In a ball mill the comminution takes place by impact and attrition The comminution in the vertical roller mill takes place by exposing a bed of material 2015年3月10日 Promising results obtained from cement industry encouraged the test studies on mineral grinding van Drunick et al (2010) presented VRM pilot plant test results where zinc ore was ground In his study it was concluded that the total specific energy of the AG/SAGball mill circuit, which was 2011 kWh/t, was reduced to 1140 kWh/t by using Copper ore grinding in a mobile vertical roller mill pilot plant2021年1月1日 Comparison among grinding technologies Ball mill V/s VRM Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, process simplifications and compactness but it is also very sensitive to vibrations and can Review on vertical roller mill in cement industry its

Cement grinding Vertical roller mills VS ball mills

For a ball mill grinding OPC to a fineness of 3200 to 3600 cm2/g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 015020 EUR per ton of cement For an OK mill grinding a similar product, the cost of wear parts depends on the maintenance procedures, ie whether hardfacing is PARISON OF GRINDING EFFICIENCY BETWEEN BALL MILLS AND VERTICAL ROLLER MILLS IN COARSE GRINDING Yakup Umucu 1, Vedat Deniz 2,Osman Mart 1 Abdi Kemal Y!ce 1, Mehmet Fahri Sara" 3COMPARISON OF GRINDING EFFICIENCY BETWEEN 2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical An energy based comparison of vertical roller mills and tumbling mills Int J Miner Process, 136 (2015), pp 3741 View PDF Analysis of vertical roller mill performance with changes in

Mill, Grinding mill All industrial manufacturers

coffee mill NEOGRIND roller horizontal compact Output: 750 kg/h 2,500 kg/h Most advanced grinder for medium capacities and demanding specialty grinds The newly designed coffee grinder NEOGRIND has been developed specifically for the high demands of filter coffee, pad/pod production (coffee capsules) and fine roller grinding mill KVS 280 horizontal for fruit stone Output: 8 t/h 12 t/h Motor power: 4 kW Machine length: 1,562 mm Roller mill for the crushing of berries and stone fruits The KVS 280 crushing mill was developed to produce the Stone mill, Stone grinding mill All industrial manufacturers2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on Analysis and Optimization of Grinding Performance of Vertical Roller

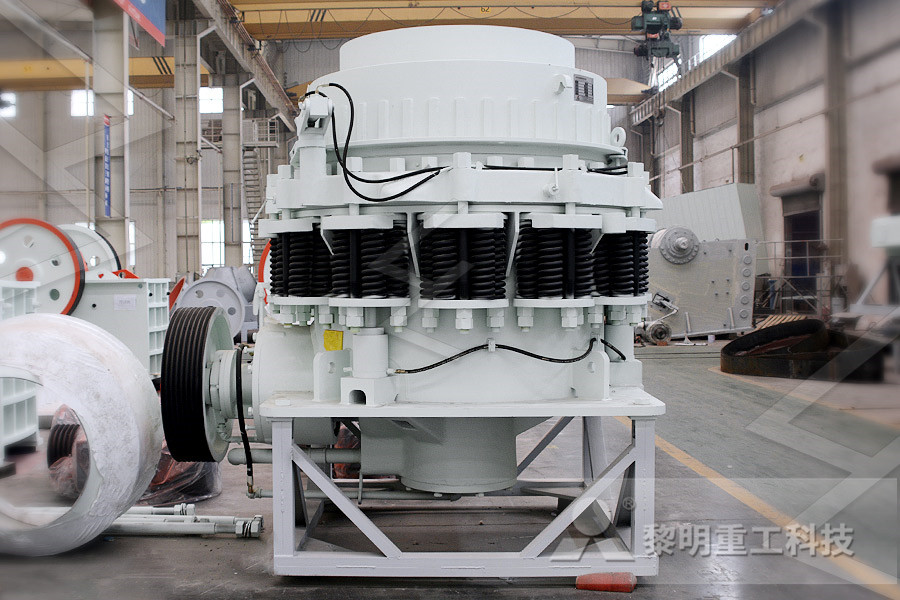

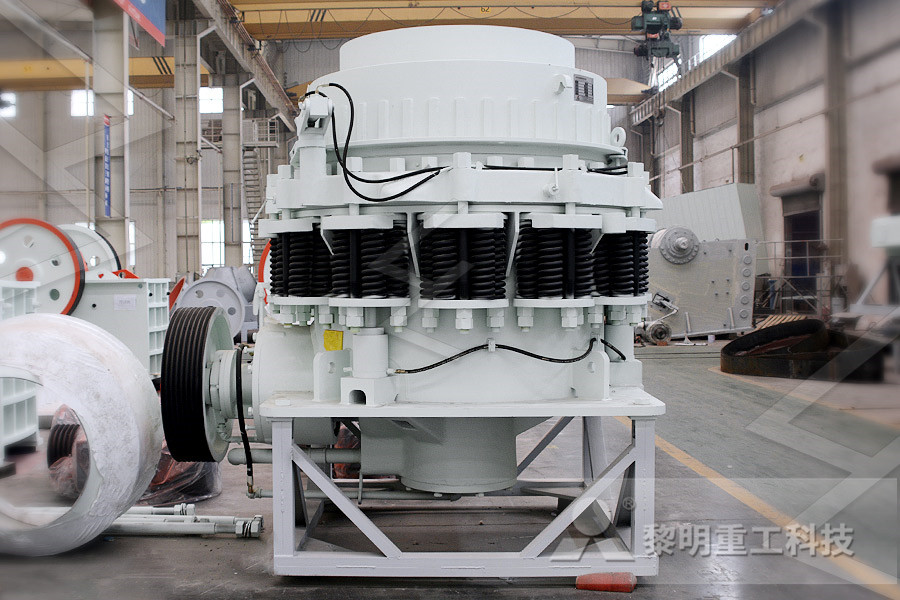

Roller mills INFINITY FOR CEMENT EQUIPMENT

Loesche roller mill (Loesche GmbH, Dusseldorf, Germany) Fig 131 shows a crosssection of a Loeschemill with a conical rotor type classifier The pressure arrange ment of the grinding rolls upon the mill feed in the grinding bowl is hydropneumatically [144] This roller mill shows the following design alterations in comparison with 2020年10月16日 For example, in the work of Podgorbunskikh EM it was shown that pure αcellulose and wheat straw are more efficiently amorphized in the AGO2 planetary ball mill, but in the activation of α Mechanochemical and Size Reduction Machines 2023年11月3日 The most common grinders are the hammer mills and the roller millsThey have been applied to the task of particle size reduction or grinding in feed milling applications Roller mills have been used in the Hammer mills versus rolles mills La Meccanica

(PDF) Stone Milling versus Roller Milling in Soft Wheat:

2019年12月19日 In the process of roller milling wheat is passed through a series of corrugated and smooth metal rollers accompanied by sifting between stages (Bayram and Durdu Öner, 2005;Cappelli et al, 2020 2021年3月12日 Comparison of cement grinding systems for ordinary portland cement at 3500 Blaine, 4% limestone Ball mill Combi grinding system Finish grinding Ball mill with cage rotor separator Roller press in semifinish mode and ball mill VRM Roller press Specel Energy consumption mill motors kWh/t 30 25 17 17 % at mill motor (ball mill 100%) % Thomas Holzinger, Holzinger Consulting, grinding 3roller mill S series horizontal for soap grinding Output: 100 kg/h 2,000 kg/h Motor power: 3 kW 30 kW Machine weight: 600, 2,100, 4,500, 5,000 kg Three Roll Mill is used for soap grinding and squeezing The main body is made of high quality steel structure, strong and stable All gears are precisely manufactured and immerged in oil 3roller mill All industrial manufacturers DirectIndustry

Laboratory mill, Laboratory grinding mill All industrial

Rotational speed: 348, 360, 428, 270 rpm Motor power: 1 kW Machine length: 610, 660, 762, 927, 1,676 mmnonstainless steel external surfaces coated with a white twopart epoxy paint • Safety trip switch across the top of the mill AVAILABLE OPTIONS: • Stainless steel type 440C hardened rolls and Tefl on end plates Find your roller mill easily amongst the 97 products from the leading brands on AgriExpo, the agricultural machinery and equipment specialist for your professional purchases Page 2 Compare this product Remove from comparison tool See the other products ROmiLL, spol s ro grain mill THOR roller mobile grain mill THORRoller mill, Roller grinding mill All the agricultural vertical for powders for limestone Final grain size: 45 µm Output: 5 t/h 18 t/h Motor power: 250, 315, 355 kW LUM Vertical Roller Mill Little abrasion wear, Long service life Based on 30 years of development experience of grinding equipment, Liming Heavy Industry produced LUM Series Superfine Vertical Roller Grinding Mill Limestone mill, Limestone grinding mill All industrial

Roller mill, Roller grinding mill All the agricultural

bean mill G8 for animal feed rice corn Production capacity: 25,000 kg/h 40,000 kg/h The Rivakka Greenmaker G8 is a tractordriven roller mill for fresh or dry grain The mill 's serratededged, hardened rollers effciently pull grain inside and carefully 2015年3月10日 The Institute of Mineral Processing at the Montanuniversitaet Leoben in cooperation with the company CEMTEC has developed a pilot scale, 200 mm table diameter, vertical roller mill for energy controlled laboratory testsThe mill provides the technical options to vary process parameters like airflow, mass flow, grinding force and An energy based comparison of vertical roller mills and tumbling mills 2022年10月1日 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industries For the sectors above, the VRM is a powerful and energyintensive grinding field [1], [2] It is used to grind slag, nonmetallic ore, and other block A cement Vertical Roller Mill modeling based on the

An energy based comparison of vertical roller mills and tumbling mills

2015年3月10日 The Institute of Mineral Processing at the Montanuniversitaet Leoben in cooperation with the company CEMTEC has developed a pilot scale, 200 mm table diameter, vertical roller mill for energy controlled laboratory tests The mill provides the technical options to vary process parameters like airflow, mass flow, grinding force and 2021年10月13日 The vertical roller mill (VRM) which has gained wide acceptance in the cement industry and is used for grinding raw materials (mainly limestone), is a promising alternative A Technical and Economic Comparison of Ball Mill Limestone Comminution with a Vertical Roller Mill @article{Swart2021ATA, title={A Technical and Economic A Technical and Economic Comparison of Ball Mill Limestone 2022年12月29日 That dictates when to utilize hammer mills So my guidelines are as follows: Use roller mills: • For mash feed down to 500 microns • For large volumes of feed • To effectively control particles of all sizes • To reduce energy costs • In front of hammer mills when doing large volumes Use hammer mills:Hammer Mill or Roller Mill: Advantages Disadvantages

Hammermills versus roller mills WorldGrain

2010年2月28日 Roller mills, particularly single pass installations, require more care and attention than hammermills in order to achieve a consistent and accurate grind Ensuring the feed is spread thinly across the face of the roller mills can present some problems as mechanical feed gates can easily become obstructed, impairing the smooth and regular 2019年1月1日 Design of Experiments (DoE) was conducted using three variables: roller compactor type, mill type and target ribbon porosity (Fig 1)The roller compactors compared in this study were: Gerteis MiniPactor (Gerteis, RapperswilJona, Switzerland), Hosokawa Bepex Pharmapaktor C250/30 (Hosokawa GmbH, Leingarten, Germany) and A systematic study of the impact of changes of roller 2023年3月4日 A traditional Sugar Mill, which currently runs at 6000 TCD, has been identified as a primary model for this upgrade By up gradation to 2roller mills, instead of 4roller or 6roller mills, this (PDF) Power Consumption Comparison between conventional and Two Roller

Review on vertical roller mill in cement industry its

2021年1月1日 Comparison among grinding technologies Ball mill V/s VRM For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over

معدات كسارة رمل السيليكا

الحصول على كسارة الحجر

استعداد الفحم محطم المحمول دي سورابايا

عملية ميكانيكية الرمال الرمال القصدير

معدات طحن الخرسانة للبيع

small used stone crusher machine in malaysia

مصنع آلات مطحنة الصلب في ألمانيا

الأخطار والمخاطر الناجمة عن سحق النبات

قادوس في مطحنة الكرة

الأسمنت الرماد المتطاير أكوام التكنولوجيا وتطبيقها في مؤسسة العلاج

آلة تكسير مصممة

الات بناء حدي

محرك يحركها كسارة الحجر

كسارة الأسطوانة ملموسة

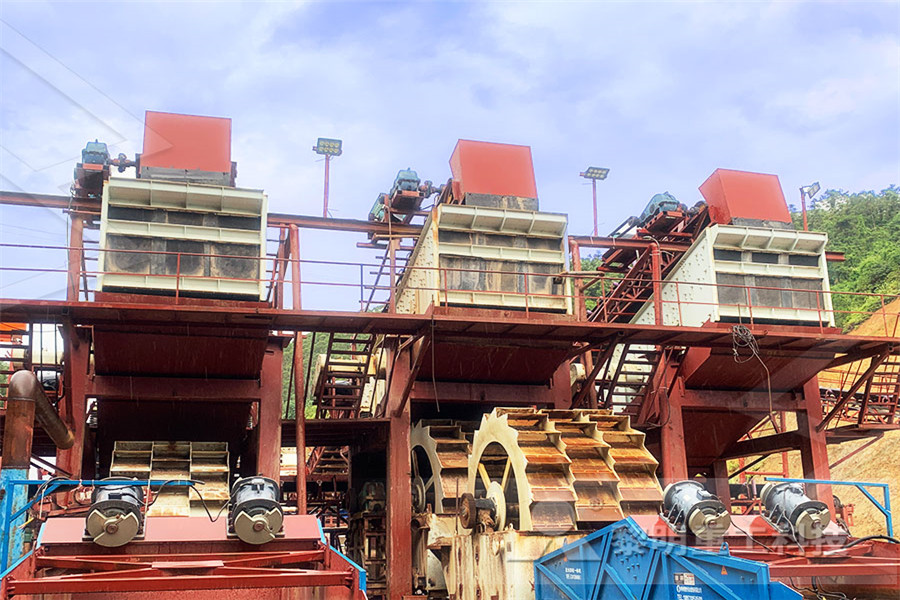

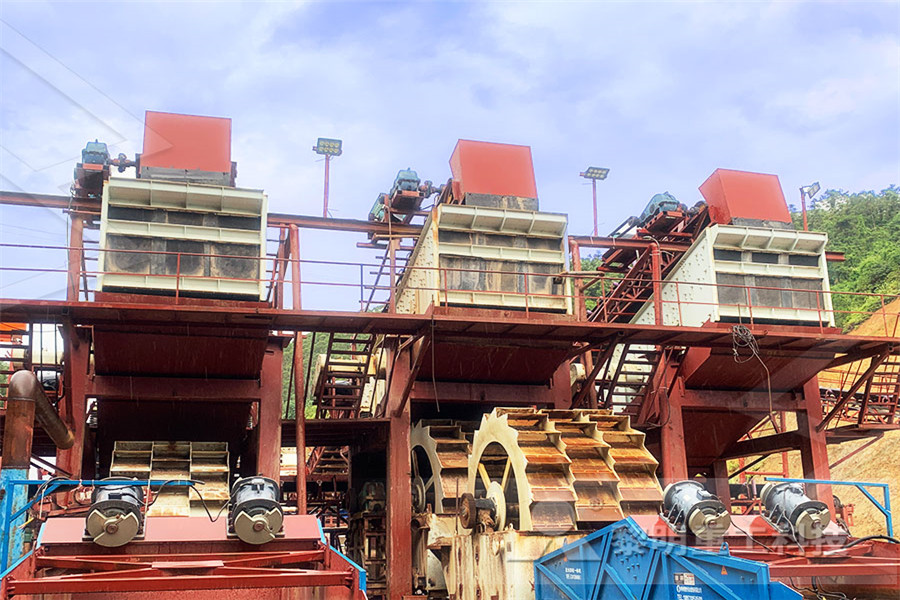

كسارات الصخور الصغيرة المتنقلة

المستخدمة في التعدين كسارة الحجر

تجهیزات معدنی سانتریفیوژ طلای کارآمد بالا

ماكينات تعبئة اسمنت مصر

تهتز الشاشة تجاوز الإعصار

ارتفاع الطلب OEM الألومنيوم 6061 T6 بدون طيار أجزاء المحرك بدون طيار

مصنع ترشيح الذهب الخام الصغير

الصين سحق الحجر الفك قدرة عالية النباتات مع افاض السعر

كسارة التعدين والبناء

تستخدم مطحنة الكرات الصغيرة

تصميم وبناء والرمل آلة النخل

كسارة الفك المستخدمة في كندا

جدوى مطحنة العلف

سعر الكسارة معقول

في طلب عروض الأسعار

عالية الأداء المزدوج لفة محطم