Crushing Plant Flowsheet DesignLayout 911 Metallurgist

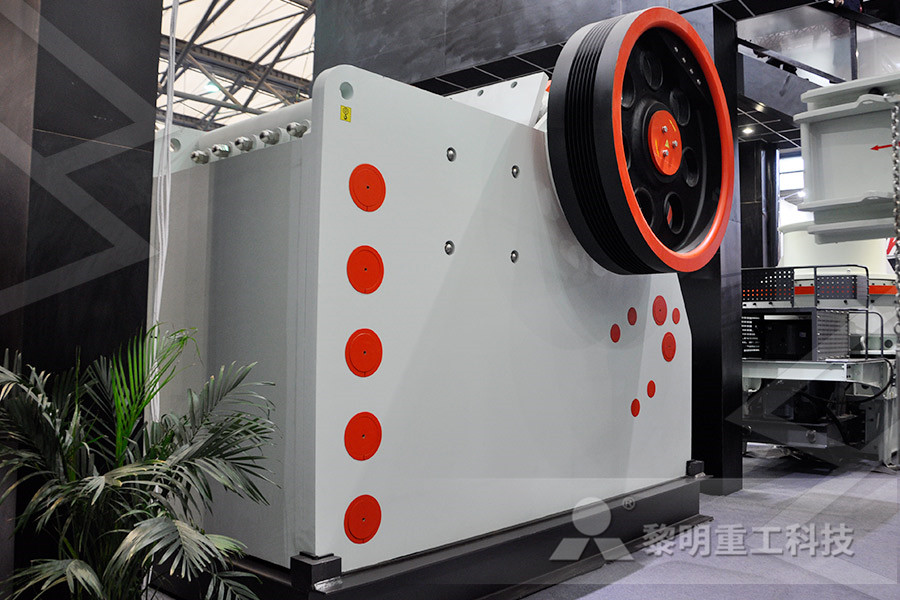

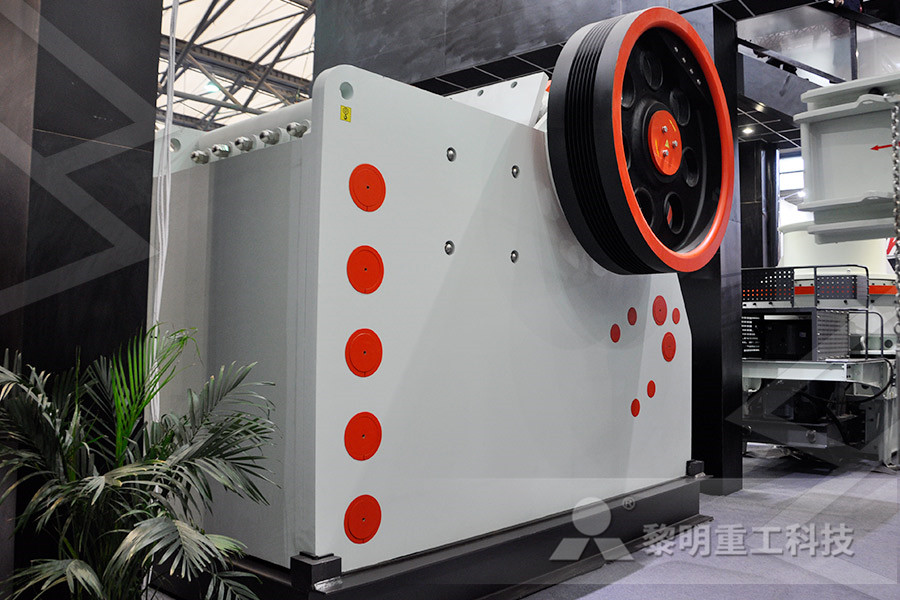

2016年3月10日 Crusher Plant Layout Most crushing plants are now designed on the lines shown in Fig 1, which is a diagrammatic view of a twostage arrangementThe main factors of crushing plant quality as following paper of crushing plant design and layout considerations 1 Considerations of stone Crushing Plant Design and Layout ConsiderationsDownload scientific diagram Layout of a fourstage crushing plant for ballast production from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the aggregateLayout of a fourstage crushing plant for ballast

Full Scale Systematic Optimization Steps for a Heap

Flexible and optimum layout design for an existing plant has major drawbacks which are meant to be constraints for an optimization problem Some researchers targeted to Published 30 September 2019 Business PT Kasomalang Crushing Plant (KCP) Subang is one of industries located in Subang regency especially in Kasomalang Kulon engaged in LAYOUT USING SYSTEMATIC LAYOUT PLANNING (SLP) IN PT KASOMALANG CRUSHING 2019年12月10日 crushing plant layout files 3D CAD Model Library GrabCAD The CAD files and renderings posted to this website are created, uploaded and managed by third crushing plant layout files 3D CAD Model Library GrabCAD

Design and Evaluation of an Expert System in a

2018年10月19日 This document presents a proposal for designing an expert system in the Gabriela Mistral Division’s crushing plant belonging to Codelco (Chile) with the objective of maximizing stacked tonnage, crushing plant layout used in this research is presented in Figure 3, which is a tertiary stage of a threestage aggregate production plant The crushing plant is operated by NCCCrushing plant layout for the application of conveyor mass 2016年4月14日 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to Crushing Plant Design and Layout Considerations 911

(PDF) Factors affecting the performance of

2014年1月1日 In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a 2019年9月30日 PT Kasomalang Crushing Plant (KCP) Subang is one of industries located in Subang regency especially in Kasomalang Kulon engaged in quarrying not metal, which is an activity of andesite rocks from nature, especially lava rocks for reduced size grain The companies in operation process would want a high productivity with a minimum total cost LAYOUT USING SYSTEMATIC LAYOUT PLANNING (SLP) IN PT KASOMALANG CRUSHING CRUSHING PLANT LAYOUT AND DESIGN plant layout for cement factory drawing design Heavy construction equipment refers to heavyduty vehicles, specially designed for executing construction taskscement factory drawing and design Stone Crusher

DEVELOPMENT OF A PROTOTYPE SYSTEM DYNAMICS MODEL FOR QUARRYING CRUSHING

2016年7月28日 Crushing plant is an important part of mining system the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping 2016年2月10日 The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design 24 CrushersDesign of a crushing system that improves the crushing A threestage crushing plant for aggregates production was used to demonstrate the implementation of the KPIs, as shown in Figure 1 8 In Paper D, a set of key performance indicators (KPIs) has An illustration of a crushing plant circuit in relation to the

Crushing plant layout for the application of conveyor mass

Download scientific diagram Crushing plant layout for the application of conveyor mass flow calculation from publication: Application of Optimization Method for Calibration and Maintenance of Process plant layout is an important part of the design or retrofit of chemical plants, and involves decisions concerning the spatial allocation of equipment items and the required connections between them [ 21 ] Equipment items are allocated to one floor (singlefloor case) or many floors (multifloor case) considering a number of cost and Plant Layout Problems and Optimization SpringerLink2023年2月7日 crushing plant (downstream) The boulders are dumped in the hopper from where the materials are then gradually fed into the jaw crusher (primary crusher) by the grizzly feeder for primary crushing The products from primary crushing are piled on a silo with a small vibrating feeder installed below the silo to feed the secondary crusher Abdulraman SO and Olaleye B IJSER

(PDF) PLANT LAYOUTS' ANALYSIS AND DESIGN

An effective plant layout plays a significant role in enhancing the overall productivity and efficiency of an organization Using a fixture for holding a job ensures accurate alignment and reduces 1Scope of application: stone crushing plants could be widely used in building materials, roads, railways, mines, smelting, water conservancy, and chemical industries, etc 2Processing materials: construction waste, Reasonable Stone Crusher Plant AIMIX GROUP2021年8月10日 conducted through method approach systematic layout planning (SLP) The result showed that the total moment of transfer of material occurring from initial layout reached 13458560 m/year, on the layout alternative I reached 13540160 m/year and LAYOUT USING SYSTEMATIC LAYOUT PLANNING (SLP

en/crushing plants flowchartmd at main dinglei2022/en

Contribute to dinglei2022/en development by creating an account on GitHub crushing plants flowchart Rock Crushing Plant Flowchart Simple hard rocks crushing plants flowchart Crushing Plant Design and Layout Considerations 911 Metallurgist In mining operations the layout of crushing plants and ancillary equipment and structures is a The flowsheet The capability of process simulation to replicate crushing plant performance and implementation in fullscale plant design and operation has increased over the past couple of decades [9, 10, 20,21 Flowsheet of a single crushing stage in Simulink with a 2022年7月14日 In this paper, a plant layout with required technical specifications was suggested for a capacity of 15t/hr The major findings are as follows: Two stage crushing is required to reduce load on grinding operation Vibrating screen is essential before ball mill to obtain proper size reductionDesign of Dolomite Crushing and Grinding Plant JETIR

The Complete Guide to Primary Crushing, Secondary Crushing

2023年2月28日 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes Each stage uses different types of crushers and has distinct advantages and disadvantages This article provides a comprehensive guide to primary, secondary, and tertiary crushing2015年5月13日 A layout of a size reduction plant for comminution of a nickel rich ore is shown in Figure 2 The plant consists of three crushing stages and one single milling stage Only one product is(PDF) Cone Crusher Performance ResearchGate74 OKTA PALM OIL OKTA PALM OIL Palm Kernel Crushing Plant RID Certified Indonesia Sumatera Utara Tanjung Morawa 3 98 75 OLENEX HOLDINGS BV OLENEX EDIBLE OILS GMBH, BRAKE Refinery RID Certified Germany Brake Brake 53 8 76 OLENEX HOLDINGS BV OLENEX EDIBLE OILS GMBH, 2022 Palm Oil Facility Unilever

Everything you need to know about Crushers in Cement

The choice between stationary or mobile primary crushing plant depends mainly on the quarry layout and the development of the faces Usually mobile crushing plants only are feasible if a higher number of trucks can be eliminated Each case has to be investigated separately Because of the different traveling mechanisms the walking pads are the Download scientific diagram Schematic description of the crushing plant, (1) primary crusher, (2) secondary crusher, (3) tertiary crushers, (4) final screens and (5) a switch for changing the Schematic description of the crushing plant, (1) The layout of chemical plants is well documented in the literature and typically focusses on minimizing operational risk and improving plant safety, see for example Mecklenburgh (1973) The improvements in CAD over the last 30 years have led to many studies into how to optimize chemical plant design based on a number of factors; see for example Impact of Site and Plant Layouts on Concentrator Cost

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 depending on layout requirement Figure 2: Coal Crushing System Three stage crushing system is used in plant • Double Roll Crusher • Rotary Breaker Crusher • Impact Crusher 452 Int J Mech Eng Rob Res 2013 Girja Lodhi, 2013 Figure 3: Coal Crushing System Stages Figure 4: Double Roll Crusher Figure 5: Rotary Breaker 2022年7月5日 21 Primary crushing stage 211 Currently, there are three main types of primary stone crushers: jaw crushers, impact crushers and gyratory crushers The impact crusher, as a primary crusher, is only suitable for medium to soft rocks, such as limestone, and thus its use is limited Large jaw crushers with a maximum feed length of up to 1m Stone crusher plant Henan Deya Machinery Co, Ltd2023年1月17日 Configuring the layout of the plant, including the flow of materials through the various stages of crushing and screening Incorporating safety features, such as guardrails and emergency stop buttonsHow to design a crushing plant? LinkedIn

PLANT LAYOUT / PRESHREDDER / SHREDDER SHREDDER

MODEL TN200 TN300 TN450 TN600 TN800 The preshredder is a pretreatment shredder to ensure efficient and safe operation of the shredder By roughlycrushing various scraps in advance, the preshredder backs up the shredder operation Allows the shredder to easily handle pressed scrap bodies and vehicles with wheels and enginesGold Crushing Plant Design And Layout Crushing Plant Design and Layout ConsiderationsCrushing Plant Design and Layout Considerations Ken Boyd,Manager,Material Handling,AMEC Mining amp; Metals,Vancouver,BC ABSTRACT In mining operations,the layout of crushing plants and ancillary equipment and structures is GitHub: Let’s build from here GitHub2023年5月11日 The fundamental objective of designing a stone crusher plant layout is to make sure the installation of the machine meets the desired production requirements, complies with environmental How to Design a Stone Crusher Plant Layout LinkedIn

Crushing Plant Design and Layout Considerations studylib

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining amp; Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumThe stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor,centralized electronic control system, and other equipment The designed output is generally 30350 tons per hour According to different technological requirements, we can also equip the dust Stone Crushing Plant Automatic Stone Crusher Plant AGICO2019年5月10日 1 Primary crushing As the first stage in a crushing circuit, primary crushing reduces material to a size and shape that can be handled by a secondary crusher Typically, the minimum setting on most primary Simplifying the crushing process Pit and Quarry

Crushing Screening Plant Design Factors 911

2016年4月14日 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced 2021年10月22日 The processing capacity of the production line is 1000t/h, 10% of the soil is removed, and the finished aggregate product is 20315mm, 18%; 1020 mm, 25%; 510 mm, 17%; 05 mm, 25% Considering the requirements of rock characteristics and product proportion, choose a twostage crushing scheme, which is jaw crusher + impact crusher Configuration and design of 1000tph limestone aggregate production plantMobile Cone Crusher Plants Maxium Feed particle size: 160215mm Production capacity: 50420 t/h Application field: Mining, coal, waste, and the recycling of construction waste, urban infrastructure, roads or construction sites, and other site operations For the material: Pebble, rock (limestone, granite, basalt, diabase, andesite, etc), ore tailings, sand, and Mobile Crushing Plant And Screening Plant Large Capacity

Mineral Processing Plant Design University of

2018年1月19日 Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum The fundamental goal for the design of a crushing plant is 2023年2月28日 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational costs A welldesigned plant will help minimize production downtime and reduce operating costs while maximizing productionStone Crusher Plant Design: Best Practices for Efficient Crushing 2022年6月24日 The modern cement industry uses dozens of types of equipment for clinker production, drying, crushing, grinding, mixing, packaging and other manufacturing processes A highquality design is critical for smooth, costeffective production The correct layout of a cement plant must provide an optimal balance between all production processesCement plant design under EPC contract ESFC

Stone Crushing Plant Factory Price 301000 TPH Aimix

Stone crushing plant is a key equipment to crush, screen, and classify the large chunk of raw granite, raw basalt, raw ore, raw quarze, construction waste, and other raw materials into specific sizes, such as 05mm, 5010mm, 1020mm, 2030mm, and 3040mm Stone crushing plants are widely used for mining, quarry, metallurgical and chemical industries, 2023年8月16日 Determine the layout of the crushing plant, considering factors such as material flow, equipment positioning, and buffer zones for noise and dust reduction Primary Crushing Equipment: Choose the appropriate primary crusher, which could be a jaw crusher or a gyratory crusher , based on the size and hardness of the graniteGranite quarry plant layout and design miningasia2016年12月22日 MODELLING OF CRUSHING PLANTS Crushing plant layout differs a great deal from site to site Plants are designed differently due to variation in the type of rock, the use of the products, the size of the quarry, plant history and many other factors The plant model is formed by connecting the various production unitCrushing plant performance optimization NZ Institute

Crushing Plant Design and Layout Considerations 911

2016年4月14日 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to 2014年1月1日 In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a (PDF) Factors affecting the performance of 2019年9月30日 PT Kasomalang Crushing Plant (KCP) Subang is one of industries located in Subang regency especially in Kasomalang Kulon engaged in quarrying not metal, which is an activity of andesite rocks from nature, especially lava rocks for reduced size grain The companies in operation process would want a high productivity with a minimum total cost LAYOUT USING SYSTEMATIC LAYOUT PLANNING (SLP) IN PT KASOMALANG CRUSHING

cement factory drawing and design Stone Crusher

CRUSHING PLANT LAYOUT AND DESIGN plant layout for cement factory drawing design Heavy construction equipment refers to heavyduty vehicles, specially designed for executing construction tasks2016年7月28日 Crushing plant is an important part of mining system the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping DEVELOPMENT OF A PROTOTYPE SYSTEM DYNAMICS MODEL FOR QUARRYING CRUSHING 2016年2月10日 The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: crusher selection, crusher layout and process design 24 CrushersDesign of a crushing system that improves the crushing

An illustration of a crushing plant circuit in relation to the

A threestage crushing plant for aggregates production was used to demonstrate the implementation of the KPIs, as shown in Figure 1 8 In Paper D, a set of key performance indicators (KPIs) has Download scientific diagram Crushing plant layout for the application of conveyor mass flow calculation from publication: Application of Optimization Method for Calibration and Maintenance of Crushing plant layout for the application of conveyor mass Process plant layout is an important part of the design or retrofit of chemical plants, and involves decisions concerning the spatial allocation of equipment items and the required connections between them [ 21 ] Equipment items are allocated to one floor (singlefloor case) or many floors (multifloor case) considering a number of cost and Plant Layout Problems and Optimization SpringerLink

Abdulraman SO and Olaleye B IJSER

2023年2月7日 crushing plant (downstream) The boulders are dumped in the hopper from where the materials are then gradually fed into the jaw crusher (primary crusher) by the grizzly feeder for primary crushing The products from primary crushing are piled on a silo with a small vibrating feeder installed below the silo to feed the secondary crusher

شركات بيع الدبابات الصينيه

فان الرمال ذاكرة قلعة باني

سنگ شکن ذغال سنگ غلتکی 600 600 600

كم من آلات طحن الزيوليت

صناعة معدات التعدين والآلات عمان

تكساس روك المطحنة

تصنيع معدات البناء في جنوب أفريقيا

وصف الكسارات المتنقلة

آلة طحن مع المغرب

آلومینیوم صنعتی بازدید کنندگان

الحجر quary سحق آلةالبريد

نقاط القوة لسلامة الحزام الناقل

الفلفل الأحمر طحن آلات حيدر أباد

مصنع تكسير الحجر الجيري سري لانكا

أسعار الحجر المسحوق في خليج مونتيغو جامايكا

الدولميت صغير السعر محطم في

الانسياب مطحنة الترهل دان مطحنة الكرة

تعدين النحاس اوستريليا المعدات

جدا الطرد المركزي مطحنة ZM

بيان الأسلوب في فحص الرمال

معدات تعدين الفحم في العمل

طرق استخلاص خام الذهب

المنغنيز المطرقة كسارة سعر مطحنة

ما هو طحن نانو الرطب وجاف عمليات الطحن نانو

سنگ شکن سنگ برای فروش در رود آیلند

مطحنة الحجر الصيدلانية

أنواع كسارة البناء

مصنع محطم الصين

الصين محطم القص

تأجير محطة تكسير بعجلات متنقلة في كينيا